In the world of modern printing, UV printing technology has emerged as a game-changer, offering unparalleled quality, speed, and versatility. UV printing uses ultraviolet light to instantly cure or dry the ink as it is printed, enabling sharp, vibrant images on a wide variety of materials. This innovative process is transforming industries from marketing and packaging to fine art and industrial manufacturing.

What Is UV Printing?

UV printing is a digital printing technique where ultraviolet light is used to cure or dry the ink immediately after it is applied to a substrate. Unlike traditional inks that rely on evaporation or absorption to dry, UV inks solidify instantly when exposed to UV light, allowing for faster production and superior durability.

How UV Printing Works

The process involves:

-

Ink Application: Special UV-sensitive inks are sprayed or jetted onto the material.

-

UV Curing: Immediately after printing, UV lamps expose the ink to ultraviolet light.

-

Instant Drying: The ink cures on contact, forming a solid, durable layer.

Because the ink dries instantly, there is no need for drying time or additional finishing steps, speeding up production.

Advantages of UV Printing Technology

1. High-Quality Prints

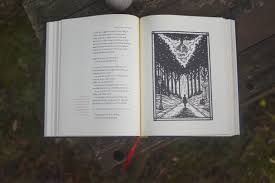

UV printing produces sharp, vibrant, and detailed images with excellent color accuracy. The inks sit on the surface, resulting in a glossy, smooth finish that enhances visual appeal.

2. Versatility in Materials

UV printing works on almost any surface, including:

-

Paper and cardboard

-

Plastics and acrylics

-

Glass and metal

-

Wood and fabric

This flexibility makes UV printing ideal for diverse applications, from promotional items to industrial components.

3. Durability and Resistance

UV-cured inks are highly resistant to scratching, fading, and water, making them suitable for outdoor use and products subjected to wear and tear.

4. Eco-Friendly Process

Since UV inks cure instantly and don’t emit volatile organic compounds (VOCs), UV printing is considered more environmentally friendly than traditional solvent-based printing.

5. Fast Turnaround

Instant drying eliminates waiting times, enabling quicker production cycles and faster delivery of printed materials.

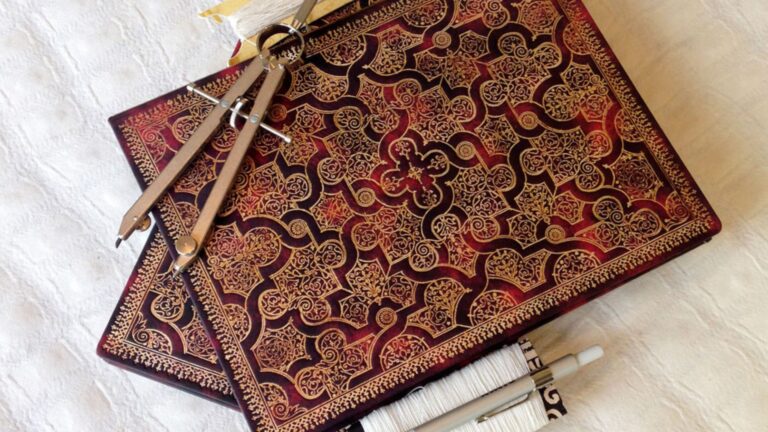

6. Special Effects and Textures

UV printing allows for printing with special textures and raised effects using clear UV varnishes. This capability adds a tactile dimension to printed materials, enhancing their uniqueness.

Applications of UV Printing

-

Packaging: Eye-catching, durable packaging with sharp graphics.

-

Signage: Long-lasting outdoor and indoor signs.

-

Promotional Products: Customized items like phone cases, pens, and gadgets.

-

Interior Decor: Printed glass panels, tiles, and wood panels.

-

Fine Art: High-quality reproductions with textured finishes.

Considerations When Using UV Printing

-

Equipment Cost: UV printers can be more expensive upfront than conventional printers.

-

Material Compatibility: While versatile, some materials may require pretreatment for optimal ink adhesion.

-

Maintenance: UV printers require regular maintenance to keep UV lamps and print heads in good condition.

Conclusion

UV printing technology offers unmatched benefits in print quality, material versatility, durability, and environmental impact. By curing inks instantly with ultraviolet light, it streamlines production while delivering vibrant, long-lasting results. Whether for commercial packaging, signage, or creative projects, UV printing is an innovative solution that continues to expand possibilities in the printing industry.