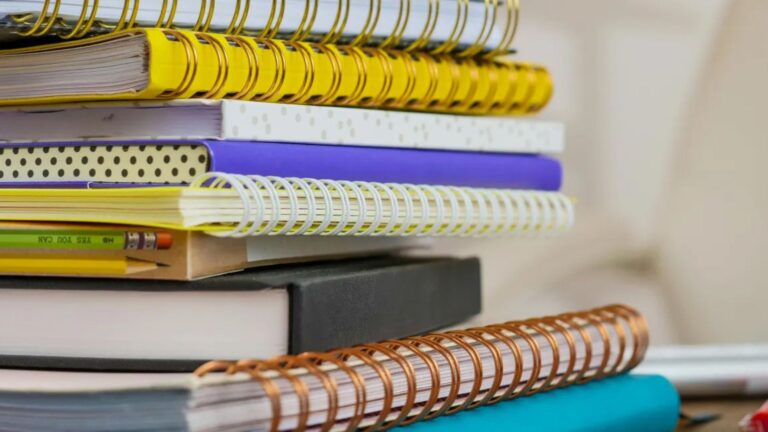

Binding plays a key role in the presentation, usability, and durability of documents, reports, manuals, and books. Two of the most common options for office and professional settings are metallic wire binding and plastic comb binding. While both serve the same purpose—holding pages together—they differ significantly in appearance, function, and long-term value.

Choosing between wire and comb binding depends on your project’s purpose, desired aesthetics, usage frequency, and budget. Here’s a detailed comparison to help you decide which option suits your needs best.

Overview of Binding Methods

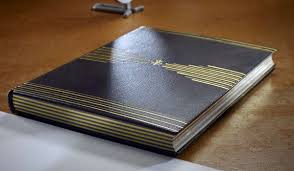

Metallic Wire Binding (Wire-O)

Also known as twin-loop or double-loop wire binding, this method uses pre-formed metal wires inserted through holes punched along the document’s edge. The wires are then closed using a wire closer machine to hold the pages securely.

Plastic Comb Binding

This method uses flexible plastic combs with curved tines that are inserted into rectangular holes along the document’s spine. The combs can be opened and closed, allowing pages to be added or removed easily.

Aesthetic and Professional Appeal

-

Metallic Wire: Offers a sleek, elegant, and professional look. The metal spine has a polished finish that’s often preferred for corporate reports, high-end presentations, and client-facing documents.

-

Plastic Comb: Appears more casual and utilitarian.

✅ Winner: Metallic Wire for visual appeal and professionalism.

When choosing between metallic wire and plastic comb bindings, durability often becomes the deciding factor for professional presentations.

Metallic wire bindings offer superior strength and a sleek appearance, making them ideal for documents that require frequent handling. Plastic comb bindings provide excellent flexibility and are easily editable, though they may not withstand heavy use as effectively.

For projects requiring both durability and visual appeal, many professionals recommend the metallic wire option.

Interestingly, the same attention to structural integrity applies to digital platforms; for instance, the Stellarspins Portal emphasizes robust security alongside user experience.

Ultimately, your binding choice should reflect both the document’s purpose and expected lifespan.

Consider the environment where your bound materials will be used before making a final decision.

Both metallic and plastic options have distinct advantages worth evaluating for your specific needs.

Durability and Longevity

-

Metallic Wire: Stronger and more durable, especially in high-use environments. It retains its shape well, although it can be bent if subjected to force.

-

Plastic Comb: More flexible but less durable. Combs can snap or lose shape over time, especially with frequent handling.

✅ Winner: Metallic Wire for strength and long-term use.

Editing and Page Replacement

-

Metallic Wire: Once closed, wire binding cannot be reopened without damaging the wire, making editing difficult. A new wire is often needed if you want to make changes.

-

Plastic Comb: Allows for easy editing.

✅ Winner: Plastic Comb for reusability and document editing.

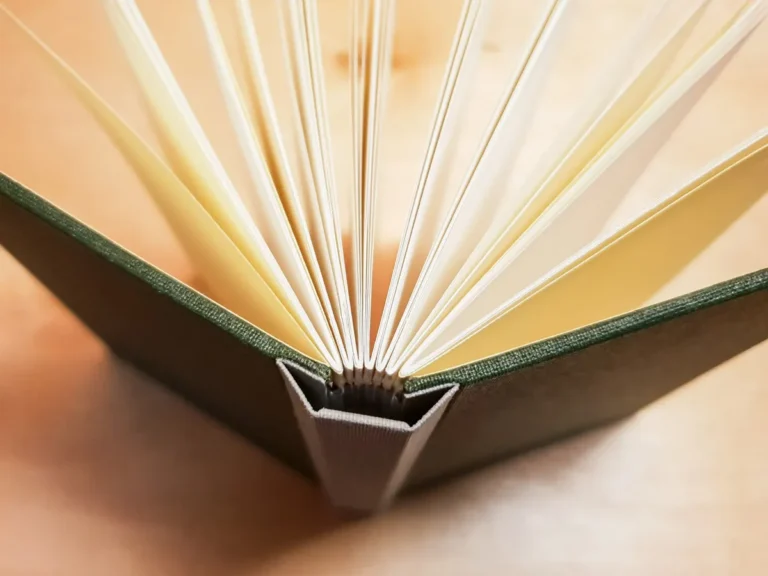

Page Turnability and Lay-Flat Capability

-

Metallic Wire: Allows pages to turn 360 degrees and lay flat without resistance, making it ideal for notebooks, calendars, and manuals.

-

Plastic Comb: Also lays flat but does not allow full 360-degree rotation. Pages may resist turning and require more effort to keep open.

✅ Winner: Metallic Wire for ease of use and presentation.

Page Capacity

-

Metallic Wire: Typically binds up to 120–150 sheets, depending on wire size. Larger capacities can require bulkier or custom-sized wires.

-

Plastic Comb: Binds up to 450 sheets, making it more suitable for large-volume documents like training manuals or thick reports.

✅ Winner: Plastic Comb for high-volume document binding.

Cost and Accessibility

-

Metallic Wire: Generally more expensive and requires a specific wire-binding machine. Best suited for high-end or low-volume applications.

-

Plastic Comb: Cheaper and widely accessible, with lower-cost machines and supplies. Great for schools, small offices, or DIY projects.

✅ Winner: Plastic Comb for affordability and ease of access.

Summary: Side-by-Side Comparison

| Feature | Metallic Wire Binding | Plastic Comb Binding |

|---|---|---|

| Appearance | Professional, sleek | Basic, functional |

| Durability | High | Moderate |

| Editing Flexibility | Low | High |

| Lay-Flat/360° Turn | Yes | Lay-flat only |

| Sheet Capacity | Up to 150 sheets | Up to 450 sheets |

| Cost | Higher | Lower |

| Ideal Use | Reports, calendars, books | Manuals, drafts, internal docs |

Conclusion

-

Choose metallic wire binding when presentation, durability, and user experience are top priorities. It’s perfect for client presentations, marketing materials, and professional documents where quality matters.

-

Opt for plastic comb binding when editing flexibility, volume, and cost are more important. It’s the go-to for educational materials, workbooks, and frequently updated reports.

Both binding methods have unique strengths, and the best choice ultimately depends on your project’s needs.