When publishing a book or producing printed materials, one of the first key decisions is choosing between hardcover and paperback binding. Both methods have distinct processes, advantages, and applications. Understanding how each binding is created helps you select the right format to match your budget, durability needs, and presentation goals.

Hardcover Binding Process (Case Binding)

Hardcover binding, also known as case binding, is a multi-step, labor-intensive process prized for its durability and professional finish.

Process Overview:

-

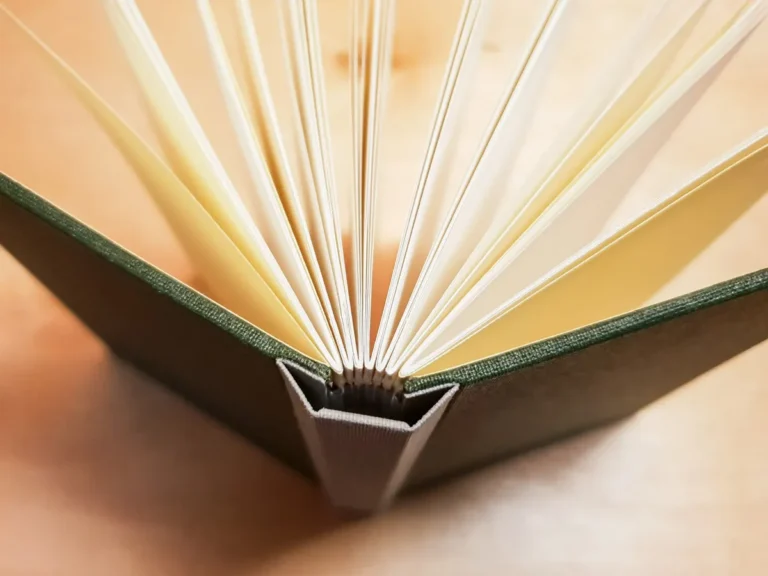

Sewing or Perfect Binding: The pages are first collated into signatures (folded groups of pages) and either sewn together or glued to form the book block.

-

Spine Reinforcement: The spine is reinforced with mull (a gauze-like fabric) and adhesive for strength.

-

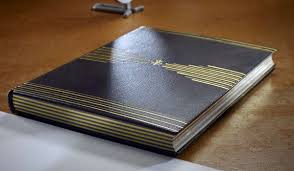

Making the Case: A hard cover or case is prepared separately, using rigid boards covered with cloth, leather, or printed paper.

-

Casing In: The book block is glued to the case using endpapers that adhere the first and last pages to the inside covers.

-

Finishing: The book is trimmed and pressed to ensure a tight, uniform shape.

Key Features:

-

Rigid, protective cover

-

Long-lasting and sturdy

-

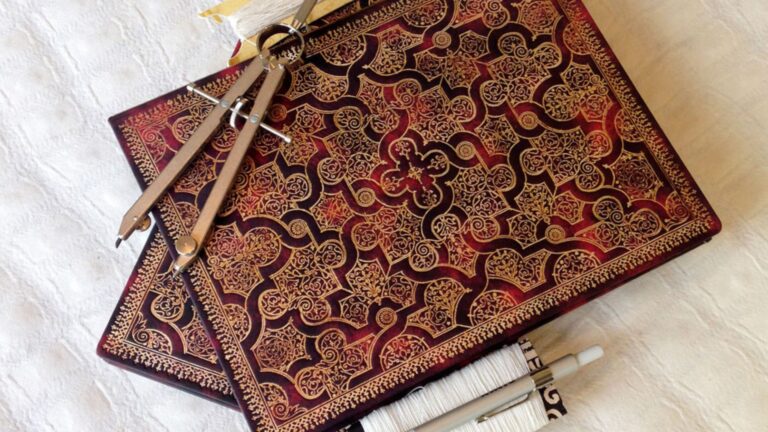

Often includes dust jackets and decorative elements (foil stamping, embossing)

-

Typically used for high-end books, reference works, and collectibles

Paperback Binding Process (Perfect Binding)

Paperback binding, commonly called perfect binding, is a more economical and faster process primarily used for mass-market books and softcovers.

Process Overview:

-

Page Gathering: Loose pages or signatures are aligned and trimmed to size.

-

Gluing the Spine: The pages are clamped, and the spine edge is roughened to improve glue adhesion.

-

Applying Adhesive: A strong but flexible hot-melt or PUR (polyurethane reactive) glue is applied to the spine.

-

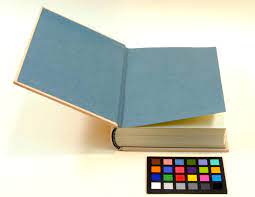

Attaching the Cover: A flexible, printed cover is wrapped around and glued to the spine and edges of the book block.

-

Trimming and Cooling: The book is trimmed to final size and allowed to cool so the glue sets.

Key Features:

-

Flexible, soft cover (often glossy or matte coated paper)

-

Lightweight and less expensive

-

Ideal for novels, manuals, catalogs, and short-run print projects

-

Generally less durable than hardcover binding

Material Differences

| Aspect | Hardcover | Paperback |

|---|---|---|

| Cover Material | Rigid board with cloth/leather wrap | Thick paper or cardstock |

| Spine Type | Sewn or glued with reinforcement | Glued only (hot melt or PUR glue) |

| Endpapers | Included for durability and aesthetic | None or simple glued inner flap |

| Durability | High – withstands wear and tear | Moderate – prone to creases and wear |

| Weight | Heavier due to rigid boards | Lightweight and portable |

Applications: When to Choose Each

| Binding Type | Ideal Uses |

|---|---|

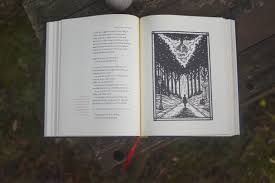

| Hardcover | Textbooks, coffee table books, archival publications, collector’s editions |

| Paperback | Fiction novels, magazines, catalogs, self-published works |

Cost and Production Time

-

Hardcover binding is more expensive and slower due to multiple steps, materials, and labor intensity.

-

Paperback binding is cost-effective and fast, suitable for large print runs and short-run digital prints.

Conclusion

Choosing between hardcover and paperback binding depends on your project’s budget, purpose, and audience. Hardcover offers unmatched durability and a premium feel, ideal for treasured keepsakes and professional publications. Paperback delivers affordability and convenience, perfect for casual reading and quick production.

Understanding the binding processes helps you make a strategic choice that balances quality, cost, and functionality.