Binding transforms loose pages into masterpieces.

In the world of bookmaking, packaging, and manufacturing, the materials used for binding do much more than hold things together. Binding materials define durability and design, shaping how long a product lasts and how it looks and feels to users. Choosing the right binding components is a critical step toward creating strong, attractive, and reliable finished goods.

The Importance of Binding Materials for Durability

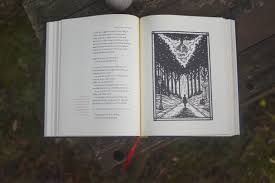

Durability is the cornerstone of any well-bound product. Whether it’s a hardcover book, a product package, or a catalog, the materials selected for binding must withstand daily wear and tear. Strong adhesives, high-quality threads, sturdy tapes, and resilient cover materials all contribute to a product’s lifespan.

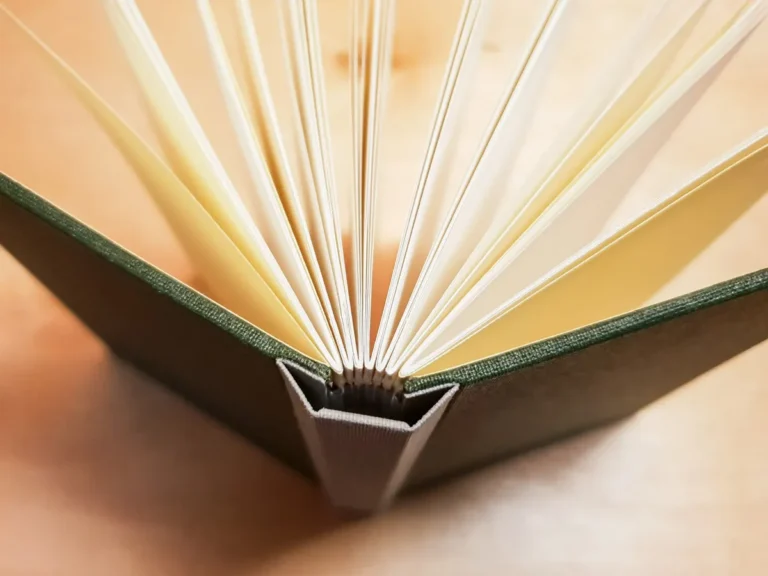

For instance, synthetic adhesives often offer superior resistance to moisture and temperature changes compared to traditional glues. Similarly, reinforced stitching or sewn binding can greatly enhance a book’s longevity, preventing pages from loosening over time.

By carefully selecting binding materials, manufacturers ensure that their products remain intact and functional for years. It’s clear that binding materials define durability and design by balancing strength with the needs of the application.

How Binding Materials Influence Design and Aesthetics

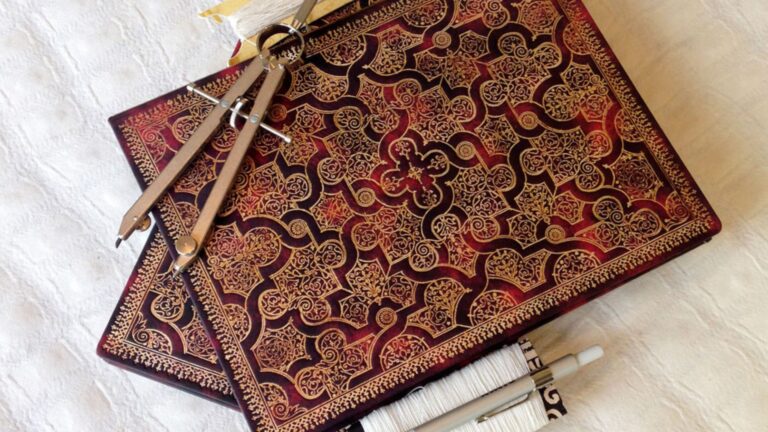

Beyond strength, binding materials play a key role in the visual and tactile appeal of a product. The texture of a book’s cover, the color and finish of binding tapes, and the style of stitching can all contribute to a product’s overall look and feel.

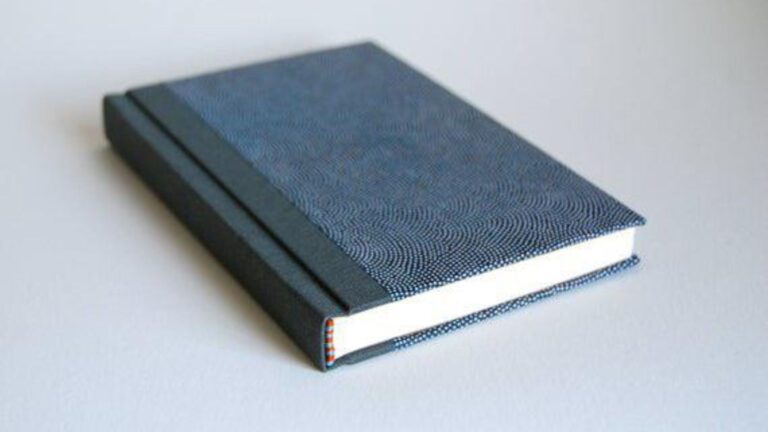

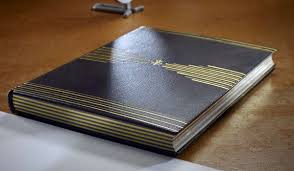

For example, leather or faux-leather covers give books a classic, luxurious appearance, while cloth-bound spines convey a more traditional or artisanal vibe. Transparent or decorative tapes can add modern flair, and colored threads can serve as subtle design accents.

Designers often use binding materials creatively to enhance brand identity and customer experience. The choice of materials can make a product stand out on shelves, communicate quality, and invite users to engage. This connection between durability and aesthetics confirms that binding materials define durability and design in every meaningful way.

Popular Binding Materials and Their Applications

Various materials dominate the binding industry, each suited to different uses. Polyvinyl acetate (PVA) glue is a popular adhesive for its flexibility and strength, ideal for perfect binding in paperback books. Hot melt adhesives are favored in packaging for quick setting and reliable seals.

Threads used in sewn binding vary from cotton to synthetic fibers, each offering different levels of resilience and appearance. Additionally, binding tapes—made from materials like polyester or paper—add extra reinforcement and decorative appeal.

Cover materials range widely: coated papers, cardboard, leather, fabric, or synthetic composites. Each choice affects durability, cost, and design possibilities. Understanding these materials helps producers align product goals with binding solutions, showcasing how binding materials define durability and design uniquely for every project.

Environmental Considerations in Binding Materials

Sustainability is increasingly important in material selection. Eco-conscious manufacturers look for biodegradable adhesives, recycled threads, and responsibly sourced covers to reduce environmental impact.

For example, water-based adhesives minimize harmful emissions, while recycled paper covers support circular economy principles. These options maintain product quality without sacrificing environmental responsibility.

In this context, binding materials define durability and design not only through physical properties but also by reflecting values of sustainability and ethics. Consumers appreciate and support brands that make conscious material choices.

Tips for Selecting the Right Binding Materials

Choosing the right materials requires balancing function, budget, and design vision. Start by assessing the product’s intended use—will it face heavy handling, exposure to elements, or frequent opening? Next, consider aesthetics and brand alignment. Finally, factor in sustainability preferences.

Consulting with experienced binders and material suppliers helps identify suitable options and innovations. Testing materials for strength and appearance before full production ensures the final product meets expectations.

By carefully curating components, manufacturers and designers prove that binding materials define durability and design, creating products that endure and impress.