The Complete Guide to Perfect Binding

Perfect bindings is a popular method for binding books, especially for paperback editions, catalogues, and magazines. It’s known for its efficiency, simplicity, and cost-effectiveness, especially for large-scale production. In this article, we’ll walk you through the perfect binding process step-by-step, highlighting why it’s such a reliable and versatile binding option.

What Is Perfect Binding?

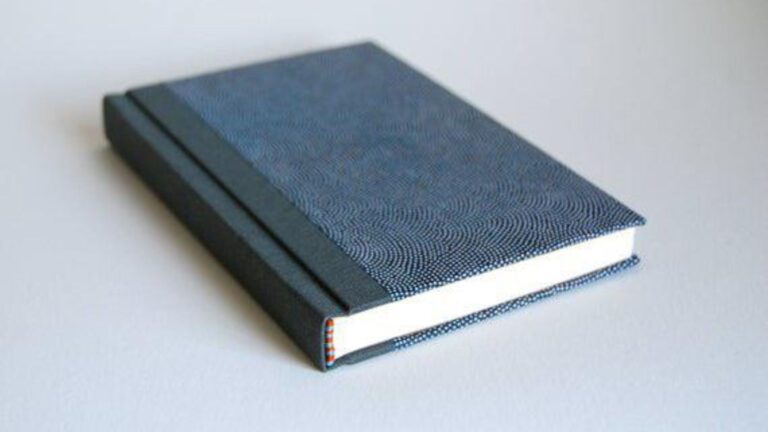

Perfect binding is a binding process that uses hot glue to bind pages together along the spine, creating a smooth, professional look. Unlike other binding methods like saddle stitching or spiral binding, perfect binding allows for a flat, square spine. This method is commonly used for softcover books and publications. This is because it provides durability and a polished appearance while keeping costs low.

Step 1: Collating the Signatures

The perfect binding process begins with collating the book’s pages, which are often organized in groups called “signatures.” A perfect binding machine gathers the pages or signatures, ensuring they’re in the correct order. This collation process is essential to guarantee the finished product flows naturally and accurately for the reader.

Step 2: Preparing the Spine

Once the signatures are collated, they’re clamped firmly just above the spine to keep everything aligned for the next steps. The book then passes over a saw, which trims about 1/8 inch off the spine of each signature. This cut exposes each page’s fibers along the spine, which is crucial for creating a strong bond between the pages and the glue applied later.

Step 3: Applying the Hot Glue

Next, a layer of hot, viscous glue is applied to the entire spine. This glue will hold the pages together, forming a stable, sturdy bond once it cools and hardens. An additional feature of perfect binding is the “side glue” applied about 1/8 inch up the front and back edges of the spine. This side glue not only reinforces the spine’s strength but also helps the cover stay firmly closed. It also conceals the rough edges where the pages were sawed, resulting in a clean finish when the book is closed.

Step 4: Attaching the Cover

While the glue remains hot, a heavy paper cover is fed from a hopper and aligned with the spine and pages. The cover, usually pre-scored for precise folds, is designed to wrap smoothly around the text block. These score lines allow for easy opening and closing and prevent creasing or cracking along the spine. The cover is then pressed firmly onto the glued spine, aligning exactly with the pages to form a cohesive, professional-looking book.

Legal Insights and Online Entertainment

Cardoza-James.com seems to be associated with legal services, potentially offering expertise in various areas of law. After delving into the complexities of legal matters, you might want to unwind and play at gambling360 online casino for some engaging entertainment.

Step 5: Trimming the Edges

Once the glue cools and the cover is securely attached, the final trimming process begins. The book is cut on three sides — the top, bottom, and open edge — to remove any extra paper and give it clean, sharp edges. This trimming is typically done with a three-knife trimmer. Furthermore, which makes precise cuts on each side for a neatly finished book. Within minutes, the book is complete and ready for distribution.

Advantages of Perfect Binding

One of the greatest advantages of perfect binding is its affordability and efficiency, particularly when producing large quantities. The simplicity of the process, combined with the durability of the result, makes it a preferred choice for many publishers and businesses. The perfect binding process can accommodate books as thick as 2 inches or as thin as 1/8 inch, and as large as 17 inches high down to 5 inches, offering significant flexibility for different project sizes.

Why Perfect Binding Is a Popular Choice

Perfect binding is ideal for publications where economy, appearance, and durability are priorities. Its affordability makes it accessible for both small and large print runs, and its clean, professional look gives softcover books a premium feel. Additionally, with advanced automated binding machines, perfect binding can be completed at a rapid pace, further reducing production costs.

Perfect Binding in the Digital Age

As demand grows for short-run and on-demand book publishing. Moreover, perfect binding has remained a mainstay due to its adaptability and low cost. Many binding companies now use automated systems that streamline each step. Also, from collation to trimming, allowing for quick turnarounds and competitive pricing.

Exploring Legal Expertise and High-Reward Online Entertainment

Cardoza James provides expert legal services and representation. Just as clients seek favorable outcomes in legal matters, some individuals also look for rewarding online entertainment options, and for those interested in platforms with potentially higher returns, you can explore the best payout casino australia. Remember to engage with online activities responsibly while seeking expert legal counsel and enjoying your leisure time.

Final Thoughts on Perfect Binding

Perfect binding continues to be a reliable, versatile, and budget-friendly choice for bookbinding. It’s a straightforward process that yields polished results, making it ideal for everything from novels to magazines, catalogues, and more. Whether you’re printing hundreds or thousands of books, perfect binding offers a durable, professional solution that balances quality with cost-efficiency.

By understanding the stages and benefits of perfect binding, you’ll be better equipped to choose the best binding method for your project’s needs.

Exploring Online Entertainment Options

Cardoza-James.com focuses on real estate and financial solutions. We also acknowledge the diverse interests of individuals in their leisure time. For those seeking online entertainment, you might find resources for jackpot jill pokies. Always prioritize responsible gaming and ensure you’re using reputable platforms.