Strong binding ensures long-lasting results

In today’s competitive world, durability is a top priority for both manufacturers and consumers. Whether it’s in packaging, construction, bookbinding, or everyday household repairs, strong binding ensures long-lasting results. Investing in the right materials and techniques for secure adhesion is not just a matter of functionality—it’s a testament to quality, safety, and long-term value.

The Role of Binding in Product Integrity

First and foremost, binding plays a critical role in holding materials together. In industries like furniture manufacturing or construction, weak binding can lead to early product failure, costly repairs, or even safety hazards. Conversely, a strong bond reinforces structural integrity, allowing products to withstand pressure, weight, and environmental changes over time.

Moreover, when businesses prioritize secure binding methods, they minimize the risk of customer complaints and returns. This not only protects a company’s reputation but also improves customer satisfaction. In essence, strong binding ensures long-lasting results that benefit both producer and end user.

Types of Strong Binding Across Industries

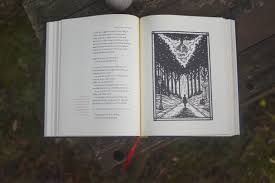

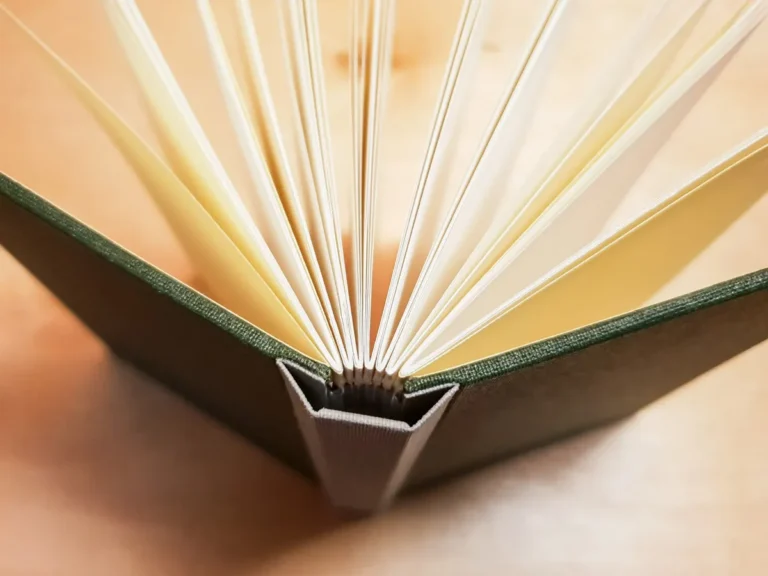

Various industries rely on different binding methods to meet their specific needs. For example, in the packaging industry, hot melt adhesives provide a fast and reliable way to seal boxes and cartons. In bookbinding, PUR (polyurethane reactive) adhesive is favored for its durability and flexibility. Meanwhile, in construction, epoxy resins and cementitious adhesives offer powerful bonding for heavy-duty applications.

Each binding type is selected based on material compatibility, strength requirements, and environmental conditions. When done correctly, these applications prove that strong binding ensures long-lasting results, even in the most demanding environments.

Choosing the Right Materials for Maximum Strength

Not all adhesives or fasteners are created equal. Choosing the right binding material involves evaluating several factors: the type of surface, exposure to heat or moisture, expected load, and longevity. For example, cyanoacrylate (super glue) works well for small, non-porous materials, but wouldn’t hold up under high-stress mechanical conditions.

Manufacturers must also consider curing time, application temperature, and potential chemical reactions. By selecting materials that form permanent bonds under specific conditions, professionals ensure that the final product is both reliable and durable. It’s a clear case where strong binding ensures long-lasting results when science meets precision.

Enhancing Product Value Through Durability

One often overlooked benefit of strong binding is the added value it brings to a product. When an item lasts longer, it reduces the need for frequent repairs or replacements. This not only saves money but also supports sustainability by minimizing waste. Consumers increasingly prefer durable goods, and businesses that deliver on that front can build brand loyalty and trust.

Furthermore, strong binding contributes to product aesthetics. For instance, clean binding lines in books or packaging create a polished, professional look. In furniture or fashion, invisible but secure stitching and adhesives elevate perceived quality. These details underscore how strong binding ensures long-lasting results that go beyond function to enhance design and value.

Future Trends in Binding Technology

As technology advances, binding solutions continue to evolve. Smart adhesives that react to pressure, heat, or moisture are gaining popularity across sectors. Eco-friendly alternatives are also in demand, offering biodegradable or recyclable options without compromising on strength. Innovations like nano-adhesives and self-healing materials are paving the way for next-generation products that last longer and perform better.

Companies that stay ahead of these trends position themselves as industry leaders. Embracing new binding technologies demonstrates a commitment to innovation, quality, and sustainability. Ultimately, these improvements reaffirm the core message: strong binding ensures long-lasting results that meet modern expectations.