Smyth-Sewn Soft Cover Binding

When it comes to bookbinding, durability and flexibility are key, especially for frequently used softcover books. A Smyth-sewn soft cover binding is a standout choice, combining elements from two popular methods—case binding and perfect binding. This unique hybrid approach is both robust and functional, allowing books to lie flat without compromising on strength. In this article, we’ll delve into the details of Smyth-sewn soft cover binding, exploring how it’s done and why it’s an exceptional choice for high-quality softcover books.

What Is Smyth-Sewn Soft Cover Binding?

Smyth-sewn soft cover binding takes the advantages of traditional case binding, known for durability, and combines them with the cost-effectiveness and ease of perfect binding. In this method, pages are organized into “signatures,” which are small groups of folded pages. Each signature is sewn together along its spine with strong nylon thread using Smyth-sewing machines. These machines, typically used for hardbound books, sew through the spine fold of each signature, resulting in a strong and flexible text “block” that will eventually be bound into a soft cover.

The result is a high-quality softcover book that can withstand repeated use, open flat for easy reading, and handle thick or coated papers that might not adhere as well in standard perfect binding.

Step 1: Folding and Collating the Signatures

Like other binding methods, the Smyth-sewn soft cover binding process starts with organizing pages into signatures. After printing, each signature is folded and collated, ensuring the correct sequence and orientation of pages. This step is essential for creating a smooth flow within the book, and it provides a foundation for the sewing process.

Step 2: Sewing the Signatures

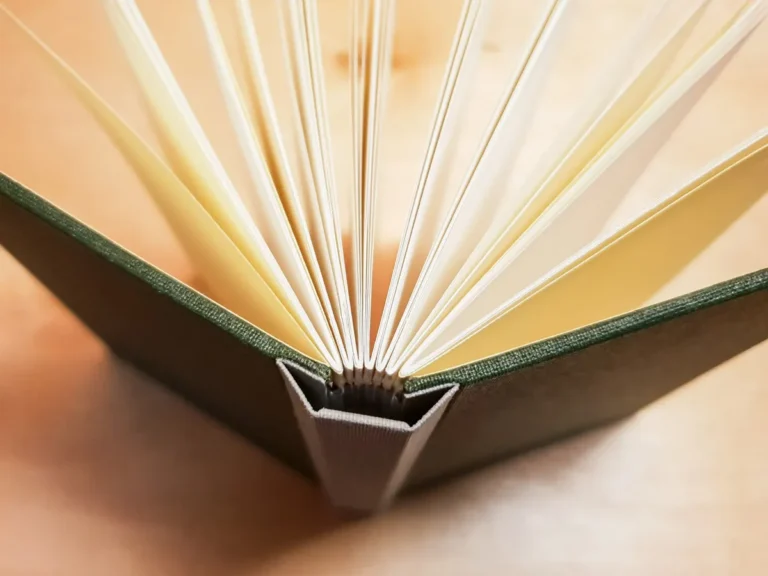

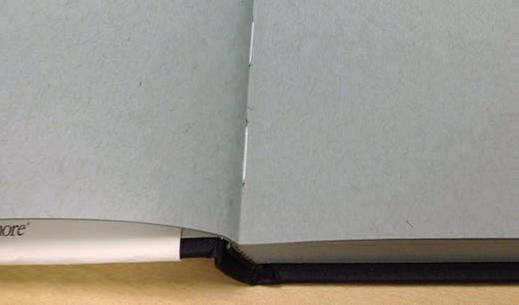

Once folded and collated, the signatures are passed through a Smyth sewing machine. These machines use strong nylon thread to stitch through the spine fold of each signature. Unlike perfect binding, where glue alone holds the pages together, Smyth sewing creates a secure bond by physically stitching each group of pages. This stitching forms a durable and flexible text block, making the book more resistant to wear and tear over time.

Step 3: Applying the Glue

After sewing, the sewn text blocks are hand-fed into the perfect binding machine. Here, a layer of molten plastic glue is applied along the entire spine. In a typical perfect binding process, the machine would saw off the back of each folded signature, leaving single pages that are glued to the cover. However, with Smyth-sewn soft cover binding, the back of each signature is left intact. This way, the glued thread and text paper create a single, cohesive unit that binds securely to the cover.

This approach preserves the sewn binding’s integrity, allowing the book to lie flat when opened. This is particularly useful for books printed on coated or glossy papers, as these materials can sometimes resist adhesion from glue alone.

Step 4: Attaching the Soft Cover

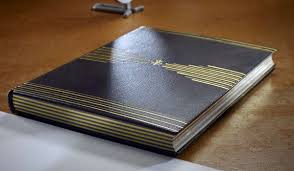

The soft cover is added to the sewn and glued text block, just as it would be in a standard perfect binding process. The cover wraps around the glued spine. Moreover, creating a finished book that combines the durability of sewn binding with the flexibility and accessibility of a softcover format. Since the spine was not sawed off, the entire text block holds together as one solid unit. Furthermore, ensuring longevity even with frequent use.

Benefits of Smyth-Sewn Soft Cover Binding

Smyth-sewn soft cover binding offers several key benefits, making it an attractive choice for publishers and readers alike:

- Enhanced Durability: By combining sewn signatures with glue, Smyth-sewn soft cover binding is much more durable than standard perfect binding. The sewn thread holds the pages securely, preventing them from coming loose over time.

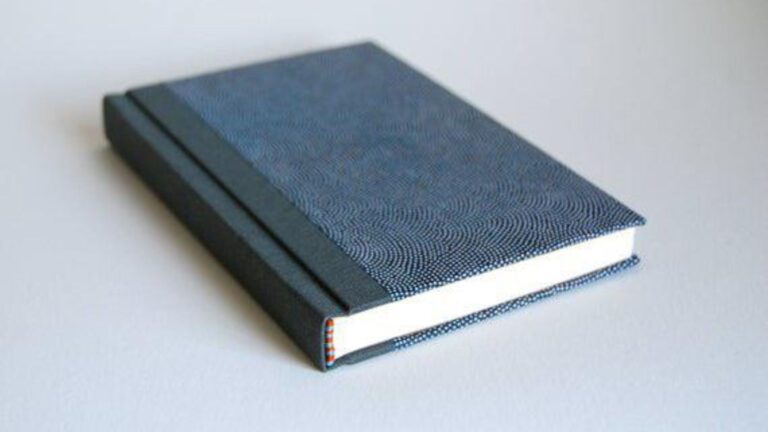

- Lay-Flat Capability: One of the standout features of Smyth-sewn soft cover books is their ability to open flat without damaging the spine. This is especially advantageous for reference books, cookbooks, and art books that need to stay open without constant handling.

- Compatibility with Coated Papers: Books printed on glossy or coated papers can sometimes struggle with adhesive binding due to the slick surface. Smyth-sewn binding overcomes this issue by reinforcing the bond with thread, ensuring that pages stay secure regardless of paper type.

- Professional Appearance: Smyth-sewn soft cover binding gives books a polished, high-quality look. The combination of a smooth cover and durable binding makes these books feel premium, making them suitable for high-end publications.

Enhancing Your Reading Experience with Quality Binding

Smyth-sewn soft cover bindings offer durability and flexibility, making your books easier to handle and longer-lasting. Attention to detail in the binding process ensures that pages stay intact even with frequent use. For those who enjoy a bit of online entertainment in their downtime, casino vip login australia provides a secure and engaging platform. Combining quality reading materials with safe online fun makes for a well-rounded leisure experience.

Final Thoughts on Smyth-Sewns Soft Cover Binding

Smyth-sewn soft cover binding combines the best of case and perfect binding, offering unmatched durability, flexibility, and a professional appearance. Whether for high-end publications, reference books, or any frequently used material, this binding method provides a polished and practical solution. By blending sewn signatures with sturdy glue, Smyth-sewn soft cover binding ensures that each book can endure years of use. Hence by this making it an excellent investment for publishers and readers alike.