Before any printing project hits the press, a critical series of steps known as the prepress workflow ensures that files are correctly prepared, color-accurate, and print-ready. Proper prepress processes help avoid costly errors, delays, and subpar print quality. Whether you’re a designer, printer, or publisher, understanding the prepress workflow and best practices for file preparation is essential for smooth printing operations and exceptional final products.

What Is Prepress?

Prepress refers to all the processes that take place after the design is finalized but before the actual printing begins. It involves checking, correcting, and converting files into a format that printing equipment can accurately interpret.

Key Steps in the Prepress Workflow

1. File Submission

Clients or designers submit their print-ready files, typically in formats like PDF, TIFF, or EPS. Files must meet specific requirements regarding resolution, color mode, and bleed.

2. File Review and Inspection

Prepress operators review files to identify issues such as low resolution, incorrect color modes, missing fonts, or transparency problems. This step ensures the file matches the print specifications.

3. Color Management

Files are checked and converted to the correct color mode, usually CMYK for printing. Color profiles (ICC profiles) are applied to maintain consistent colors across devices.

4. Imposition

Imposition arranges multiple pages on a single print sheet to optimize paper usage and printing efficiency. This step also considers folding, cutting, and binding requirements.

5. Proofing

Digital or physical proofs are created for client approval. Proofs simulate the final print colors and layout, allowing for corrections before full production.

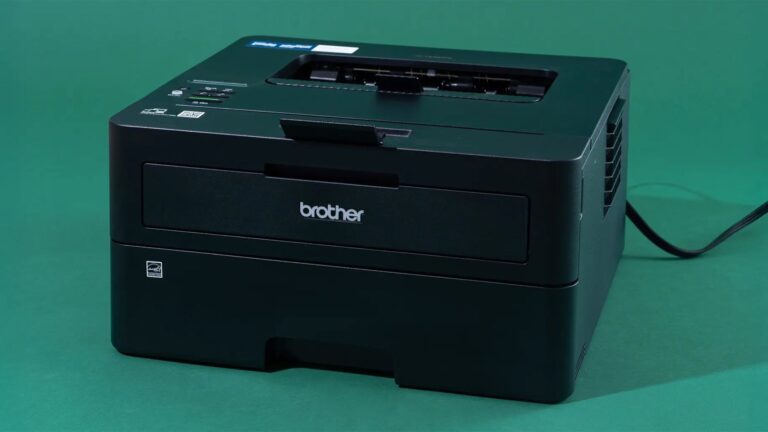

6. Plate Making

For offset printing, printing plates are produced based on the final files. These plates transfer the ink onto the paper during printing.

Best Practices for File Preparation

Use the Correct Color Mode

Ensure images and graphics are in CMYK mode rather than RGB, as printers use cyan, magenta, yellow, and black inks. RGB files can cause unexpected color shifts if not properly converted.

Maintain High Resolution

Images should be at least 300 DPI (dots per inch) at the final print size to ensure sharp, clear prints. Lower resolutions result in pixelated images.

Include Bleed and Crop Marks

Add a 3-5 mm bleed beyond the trim edge to prevent white borders after cutting. Crop marks guide where the page should be trimmed.

Embed Fonts or Convert to Outlines

To avoid missing font issues, embed all fonts in your PDF or convert text to outlines. This guarantees text appears correctly in the final print.

Flatten Transparency

Transparent elements in files should be flattened to prevent printing errors, especially when combining layers or using spot colors.

Use Standard File Formats

Submit files in widely accepted formats like PDF/X-1a or PDF/X-4, which are designed for reliable print reproduction.

Common Prepress Problems to Avoid

-

Low-resolution images: Lead to blurry or pixelated prints.

-

Incorrect color modes: Cause dull or inaccurate colors.

-

Missing fonts: Result in font substitutions and layout changes.

-

Lack of bleed: Leads to unwanted white borders after trimming.

-

Unflattened transparency: May cause unexpected artifacts in print.

Why Prepress Matters

The prepress workflow serves as the quality control stage, preventing errors that can ruin printed materials. By catching issues early and preparing files correctly, printers can save time and costs while delivering superior results. A smooth prepress process benefits everyone—from designers to clients to print service providers.

Conclusion

Understanding and following the prepress workflow and file preparation best practices are vital for any successful printing project. Attention to detail in color management, resolution, file format, and layout ensures your designs translate perfectly from screen to paper. Investing time in prepress preparation reduces costly mistakes and guarantees that the final printed product meets or exceeds expectations.