The Case Binding Process

Case binding is the method used to create hardcover books. It involves several detailed steps, each essential for ensuring a strong and durable final product. Here’s a simple overview of the case binding process:

1. Folding

First, large printed sheets of paper are folded into signatures. Each signature contains a group of pages. The number of pages per signature depends on the press and paper type, but it usually ranges from 8 to 32 pages. Folding must be precise to ensure the pages align correctly and prevent errors later.

2. Tipping/Endsheets

Next, we attach endsheets to the first and last signatures. Endsheets are heavy paper sheets that help bind the text block to the cover. The grain of the paper must run parallel to the fold to ensure strong bonding.

3. Collating

Once the endsheets are in place, we collate the signatures. This means arranging them in the correct order to form the complete text block. During collating, any additional materials, such as inserts or color plates, are also added.

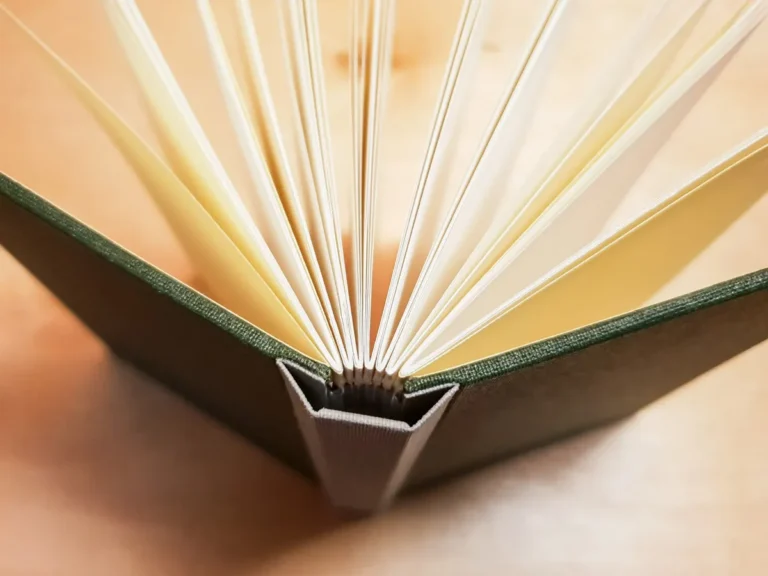

4. Smyth Sewing

The collated signatures go through a Smyth sewing machine. This machine uses strong nylon thread to sew the signatures together at the spine. It secures the pages while allowing the spine to remain flexible. Smyth sewing is a crucial step for creating a durable, high-quality book.

5. Smashing and Gluing

After sewing, we press the text block to flatten the folds. Then, we apply glue to the spine to secure the stitches. The glue is dried using heat to ensure a strong bond. This step is necessary to hold everything together.

6. Trimming

Next, we trim the text block on three sides. This removes excess paper and ensures the pages are even. Trimming gives the book a neat, professional appearance and prepares it for the final casing.

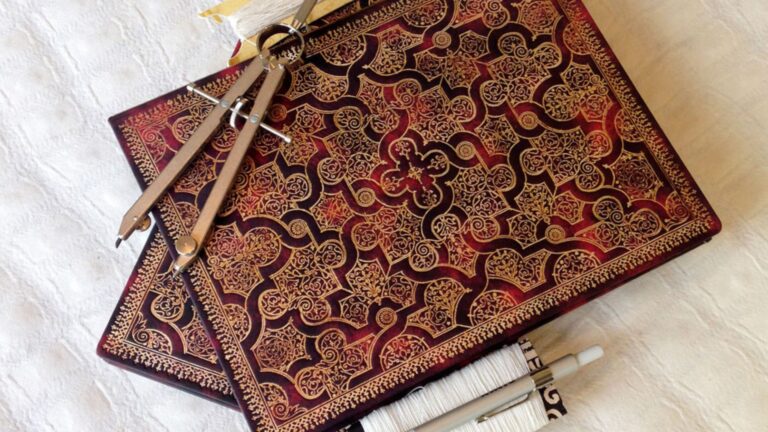

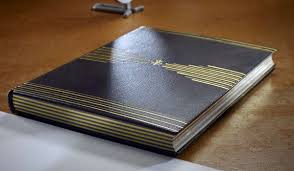

7. Making the Case

While preparing the text block, we create the case, or cover. We cut thick boards and apply cover material, such as cloth or paper. We glue the material to the boards and fold the edges neatly to create a smooth, wrinkle-free cover.

8. Stamping and Embossing

After the case is made, we apply any decorative elements, such as foil stamping or embossing. These details give the book its unique look, whether it’s a title, logo, or design.

9. Rounding and Backing

For thicker books, we round the spine. This involves pressing the spine into a concave shape, making the book easier to open. Thinner books remain flat. We then back the spine to ensure the cover boards stay in place and the book opens smoothly.

10. Backlining

Backlining adds strength to the book. We apply layers of glue, cloth, and paper to the spine. This reinforces the bond between the text block and the cover. It also helps prevent the spine from breaking over time.

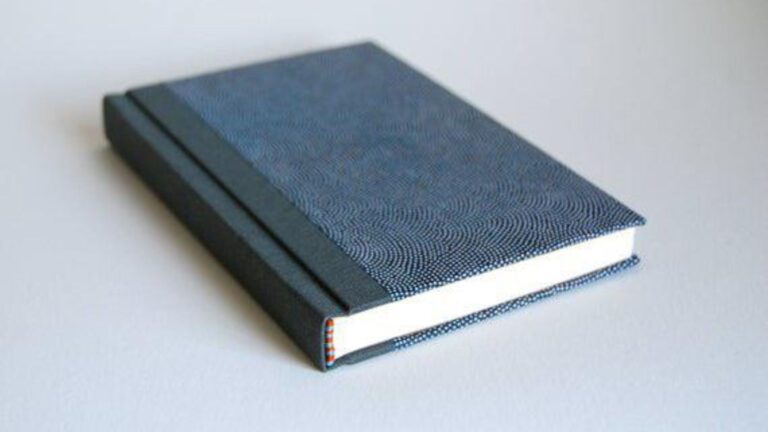

11. Casing In

We glue the text block into the case. The endsheets attach to the inside of the cover, securing the book together. We carefully position the text block inside the case for a perfect fit.

12. Building In

We place the book between heated clamps to press it securely. This ensures a strong bond between the text block and the cover. The heat dries the glue quickly and removes any air bubbles or wrinkles.

13. Inspection and Final Packaging

Once the book is finished, we inspect it for defects. We correct any issues before packing it for shipment. If needed, we add a dust jacket or shrink-wrap the book to protect it during delivery.

Discover the World of Cardoza James

Explore the unique collections and artistic vision of Cardoza James. Delve into a world of creativity and craftsmanship. For those with diverse online interests, you can find information on top online casino sites.

Our binding process respects the integrity of your work. Each bound document reflects careful attention to design, ensuring that form and function go hand in hand. We serve a wide range of clients—from academic institutions to independent creators—who value quality and consistency in every fold and stitch.

When it comes to finding reliable services online, trust and transparency are key. Whether you’re seeking craftsmanship in binding or fair play in digital entertainment, platforms that prioritize user satisfaction stand out. One such platform is casino corner, which provides helpful insights and curated listings for Canadian online casinos. Just like our approach to binding, they emphasize precision, quality, and user trust.

Legal Insights and Online Gaming

At Cardoza-James, visitors can access valuable legal insights and expert advice on a range of topics. For a fun and interactive break, Jokacasino Games offers a wide variety of engaging online games. Both platforms aim to provide useful and entertaining experiences for their audiences.

Conclusion

Case binding is a precise and detailed process. It creates strong, durable hardcover books that last for years. From folding and sewing to trimming and casing, every step is crucial for producing a high-quality book. Whether you’re binding a personal project or a corporate report, case binding ensures the finished product will meet your expectations for durability and presentation.