Binding has come a long way from hand-stitched manuscripts and glue-laden hardcovers. Today, advances in material science and manufacturing are transforming the way documents are assembled and finished. With rising demands for durability, sustainability, automation, and design flexibility, the binding industry is embracing innovation like never before.

In this article, we explore the latest innovations in binding material technology, covering smart adhesives, eco-friendly alternatives, customizable polymers, and digital integration. These breakthroughs are not only enhancing functionality but also redefining what’s possible in modern bookbinding and print production.

Smart Adhesives: Precision and Performance

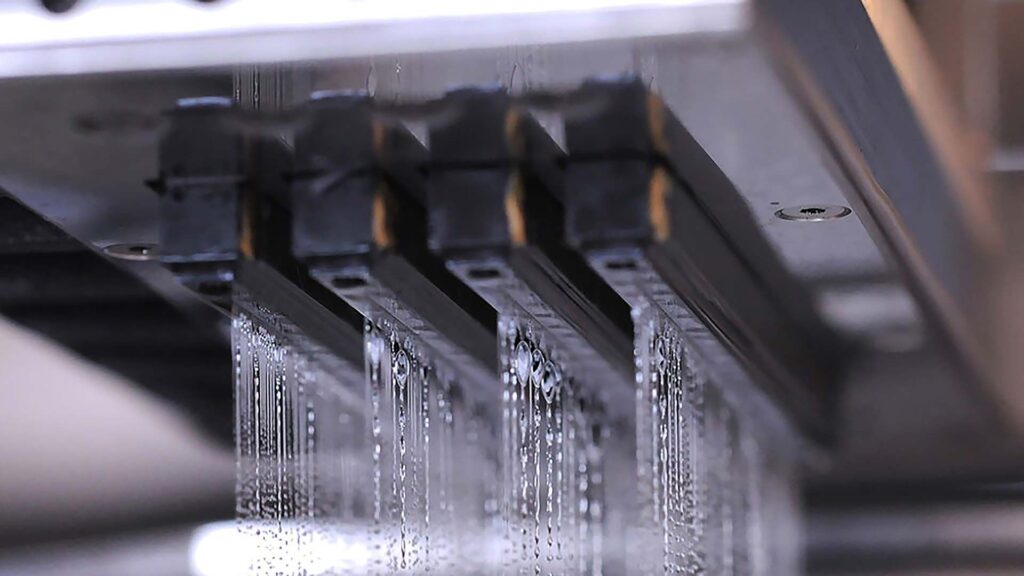

One of the most significant advancements in binding technology is the development of smart adhesives—engineered glues that respond to environmental or mechanical stimuli for optimal bonding.

Key Innovations:

-

Temperature-controlled adhesives that activate at precise heat levels, reducing waste and improving efficiency.

-

Pressure-sensitive microcapsule adhesives that allow for strong bonds without heat application.

-

Reactive polyurethane (PUR) adhesives, now improved for faster cure times and longer shelf life, offering unparalleled strength and flexibility.

✅ Impact: Smart adhesives have made thermal and perfect binding more reliable, adaptable, and cost-efficient—especially for high-speed digital print environments.

Biodegradable and Plant-Based Binding Components

Sustainability is driving the development of biodegradable, compostable, and plant-based binding materials that match or exceed the performance of traditional plastics.

Recent Developments:

-

PLA (Polylactic Acid) binding coils made from renewable corn starch, suitable for spiral-bound books and notebooks.

-

Wheat starch pastes and vegetable-based glues now enhanced with mold inhibitors for longer shelf life in archival projects.

-

Paper-based binding spines and strips laminated with water-based coatings for added strength without compromising recyclability.

✅ Impact: These innovations support circular design and enable environmentally responsible publishing, packaging, and document presentation.

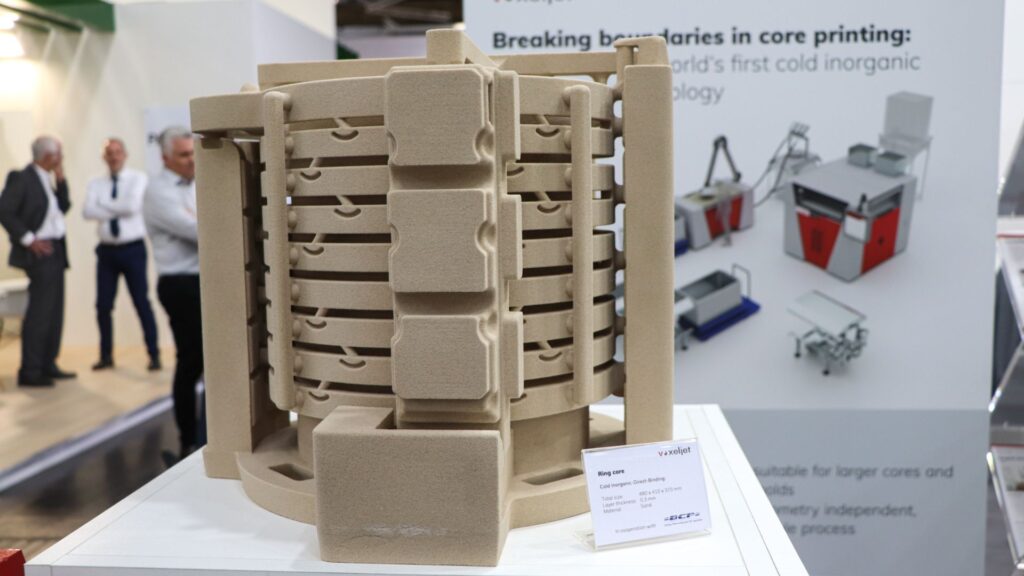

3D-Printed Binding Components

3D printing technology is entering the binding world with customizable and on-demand binding elements such as:

-

Binding combs and coils tailored to specific document thicknesses

-

Decorative spines and closures for limited edition or artistic projects

-

Ergonomic handles or tabs for easier page turning and document navigation

Materials used include recycled PLA, flexible TPU, and even wood-filled filaments for a natural look and feel.

✅ Impact: 3D printing enables rapid prototyping, customization, and reduced inventory waste for short-run, bespoke, or high-design projects.

Nanomaterials and Reinforced Fibers

Material scientists are leveraging nano-coatings and fiber composites to enhance the durability and longevity of binding materials.

Examples:

-

Nanocellulose-reinforced paper for ultra-strong, tear-resistant covers and pages

-

Hydrophobic coatings that repel moisture without affecting recyclability

-

Antimicrobial binders and coatings for books and manuals used in healthcare and education

Impact: These materials create safer, more durable products suited for high-touch or high-traffic environments—without adding bulk or weight.

Digitally Responsive Binding Elements

As printed and digital media converge, binding technology is evolving to support interactive or hybrid applications.

Emerging Concepts:

-

RFID-embedded spines for real-time tracking of books in libraries or logistics

-

Augmented reality-enabled covers made from printable conductive materials

-

QR/NFC chip integration into the binding spine to link physical books to digital content

Impact: These innovations bridge the physical-digital divide, especially in education, marketing, and publishing.

Automation-Ready Binding Supplies

To support high-volume production, binding materials are now being developed with automation in mind.

Features Include:

-

Pre-collated, barcoded cover sets for quick machine recognition

-

Heat-activated strips with uniform thickness for seamless thermal binding

-

Self-adjusting wire and coil systems compatible with robotic arms in print finishing lines

Impact: These advances streamline workflow, reduce operator error, and increase throughput in commercial printing operations.

Modular and Reusable Binding Systems

Eco-conscious consumers and businesses are embracing reusable binding systems designed to reduce waste and extend product life.

Examples:

-

Modular screw-post systems made from aluminum or bamboo

-

Tool-free binding systems that allow users to remove and insert pages without damaging the spine

-

Refillable notebooks with custom elastomer or magnetic bindings

Impact: These systems support sustainable design, personalization, and long-term usability, particularly in creative and professional sectors.

Conclusion

From plant-based coils and nanotech coatings to smart adhesives and interactive spines, the future of binding material technology is bold, efficient, and sustainable. These innovations are not only elevating product performance but also enabling businesses to meet evolving consumer expectations around design, speed, and environmental responsibility.

Whether you’re a printer, publisher, designer, or educator, staying informed about these advances opens the door to smarter, greener, and more innovative binding solutions.