Offset printing ensures sharp, consistent quality.

In the world of professional printing, few methods rival the reliability of offset printing. Whether producing magazines, books, packaging, or promotional materials, offset printing ensures sharp, consistent quality across every piece. Its time-tested technology delivers precise color, fine detail, and durable results—even on large-scale runs. While digital printing has gained popularity, offset remains the gold standard for volume, quality, and brand consistency. Let’s explore why offset printing still plays a vital role in today’s print production.

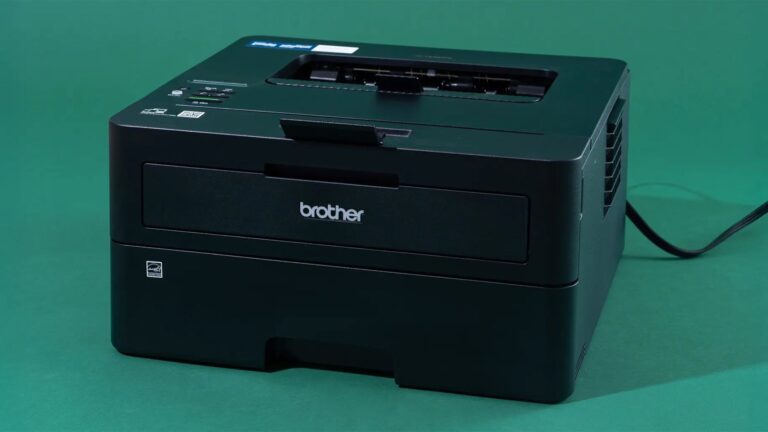

The Basics of Offset Printing

Offset printing works by transferring ink from a plate to a rubber blanket and then onto paper. This indirect method reduces wear on the printing surface, resulting in greater longevity and consistent output. It’s ideal for high-volume jobs where quality cannot be compromised. Additionally, the process supports a wide range of paper types and finishes. Because of its stability, offset printing ensures sharp, consistent quality over thousands of impressions—something digital methods struggle to match at scale.

Why Offset Stands Out in Quality

When it comes to image clarity and color fidelity, offset printing delivers unmatched results. The plates used are laser-etched with high-resolution images, enabling incredibly fine lines and details. More importantly, colors are mixed using the Pantone or CMYK systems, giving complete control over hue accuracy. Whether printing corporate materials or premium packaging, offset printing ensures sharp, consistent quality that meets the highest professional standards. The output looks the same from the first page to the last, even in long runs.

Cost Efficiency at High Volumes

Although initial setup costs for offset printing are higher due to plate creation, it becomes cost-effective with large quantities. Once the press is running, the per-unit cost drops significantly. This makes offset the preferred choice for bulk printing projects like newspapers, catalogs, and textbooks. Businesses benefit from both superior quality and reduced costs as volume increases. So, for companies needing consistent brand presentation at scale, offset printing provides excellent return on investment.

Consistency Across Every Print

One of offset printing’s greatest strengths is its consistency. Once the press settings are locked in, the output remains identical throughout the entire print job. This is particularly important for brands that rely on exact color matching and uniform presentation. Whether printing 500 flyers or 50,000 brochures, offset printing ensures sharp, consistent quality with no degradation in performance. The predictability of results builds confidence and trust, especially for high-stakes or regulated industries.

Ideal for Specialty Finishes

Offset printing also excels in delivering specialty finishes that enhance visual appeal. From spot UV coating to metallic inks and embossing, offset presses handle complex jobs with precision. These options allow designers to push the boundaries of creativity while maintaining technical accuracy. For example, luxury product packaging often relies on offset printing to achieve a premium look and feel. By combining high-resolution print with finishing techniques, brands can elevate their materials beyond basic presentation.

Offset Printing in a Modern World

Despite advances in digital technology, offset printing continues to evolve. Today’s presses use automation and computer-controlled calibration to reduce setup time and waste. Additionally, eco-friendly inks and sustainable papers are now common in the offset process. These improvements make it possible to maintain quality while aligning with environmental goals. Offset printing ensures sharp, consistent quality while keeping pace with modern demands—proving its relevance in both traditional and future-forward markets.